- Language

- 🇪🇸

- Joined

- Jan 14, 2024

- Messages

- 68

- Reaction score

- 37

- Points

- 18

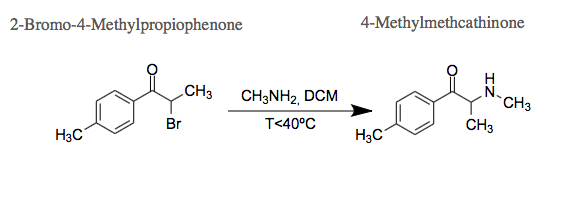

Dichloromethane (DCM) is used as a solvent. It has a low boiling point (~40 °C) and synthesis procedures take little time.

Working conditions:

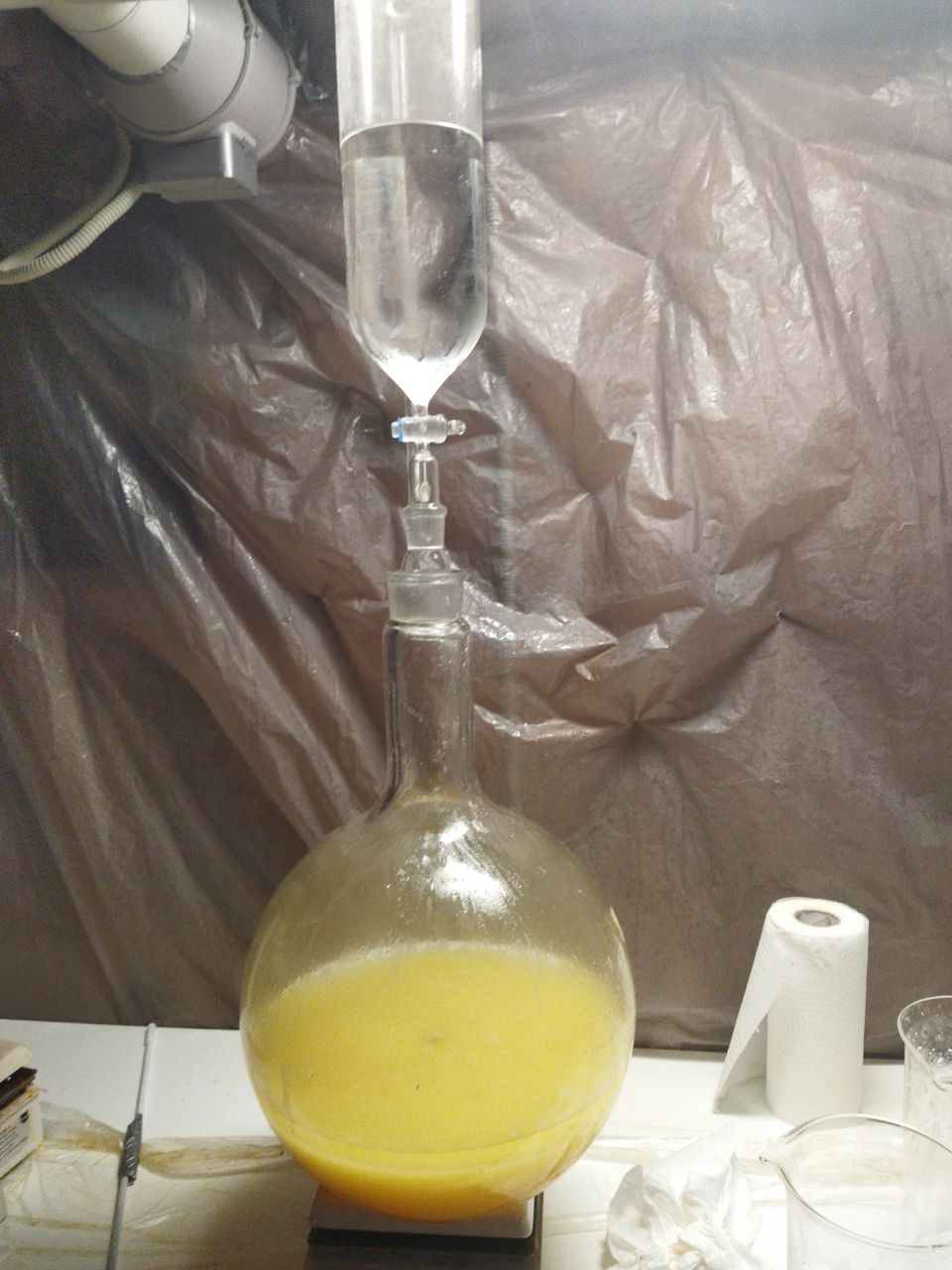

1000g of 4'-methylpropyrophenone (cas 5337-93-9) and 3000 ml of DCM are placed in a 10 l flask and shaken until a homogeneous solution is obtained.

A portion of bromine (Br2) 1000 g, 330 ml is poured into a dropping funnel.

It is important to know: Working with bromine requires special safety measures because the substance is highly corrosive and toxic. Any surface that comes into contact with bromine will be completely ruined. It is best to use a long graduated pipette or a graduated cylinder to measure the volume of this substance. Bromination should be carried out in the open air or in a well-ventilated room because bromine is very volatile. The procedure is not complicated but requires attention. All glassware used for bromine manipulations must be cooled and absolutely dry.

50 mL of hydrochloric acid (36% aqueous HCl) is added to the reaction mixture. This is the catalyst for the bromination reaction. Gentle stirring is activated and the addition of bromine is started.

The first portion of bromine, ~50 mL, is added. The solution turns brown and eventually discolors. This means that the bromination reaction has taken place. Wait for this moment, and do not pour in all the bromine at once to avoid a violent exothermic reaction with subsequent boiling of the solution.

Bromine is added from the dropping funnel to the solution dropwise, when the first portion of Br2 discolors, for a smooth reaction course. If the solution starts to boil, the addition of bromine should be stopped until the solution cools to 30-35 °C.

Important to know: Hydrogen bromide is released during bromination. It is a caustic (acidic) white gas. Respiratory and eye protection (full face mask) and a well ventilated fume hood are required.

It is necessary to make sure that the reaction is finished after all the bromine has been poured out: the reaction temperature stops rising, the solution stops discoloring. The reaction mixture is then stirred for 30-60 min.

The obtained solution is washed from the remaining bromine, which positively influences the quality of the final product. The reaction mixture is washed with an equal volume of 10% sodium thiosulfate (Na2S2O3) solution or 10% sodium bicarbonate (NaHCO3) solution. The solution is shaken well for 10 min, the layers are clearly separated. The lower organic layer is taken for further manipulations. The upper layer is discarded.

The reaction mixture is then washed with an equal volume of water to neutral pH. The washing procedure of the organic layer can be repeated several times, if necessary. The reaction yield of 2-Bromo-4'-methylpropyrophenone (cas 1451-82-7) is ~1400g, which is already dissolved in DCM.

Methylamination

A 40% aqueous solution of methylamine is added to the above reaction solution. This reaction is also exothermic, so the methylamine is added at a slow rate to prevent the solution from boiling. This influences the yield of the reaction. An excess of methylamine is taken up as some of it evaporates during the reaction. The average ratio is 2 ml per 1g of 2-Bromo-4'-methylpropyrophenone. 2800 ml of 40% aqueous methylamine solution is added to 1400 g of 2-Bromo-4'-methylpropyrophenone. The methylamine is added through a dropping funnel in a fine flow or divided into 2-3 portions and poured in equal parts with moderate stirring without splashing.

The reaction mixture is stirred for 2 hours at 40 °C.

Separation and purification of the free base

After processing the mixture from the previous part, the free base is washed and separated. The lower organic layer is separated from the upper aqueous layer. The organic layer is washed as described in step 7 (same procedures), the upper layer is discarded. The washing of the organic layer is repeated several times until the methylamine odor disappears.

The yield of the DCM solution of mephedrone free base (4-MMC) is ~3000 ml. If the organic layer is too small after methylamination, 1 to 2 L DCM is added. This will help to better extract the free base of 4-MMC. Then, separate the layers and discard the aqueous layer.

It is very important to separate the organic layer from the water. To be sure, you can put the DCM solution in the freezer, the remaining water will freeze and will be easy to separate. Also, you can dry your solution with anhydrous magnesium sulfate (MgSO4). If water remains, problems may arise with precipitation in the next step during acidification.

Acidification 14. The resulting free mephedrone base in DCM is treated with hydrochloric acid. The best method for salt production is HCl gasification. An aqueous solution of 35-38% hydrochloric acid HCl in acetone or isopropanol in the ratio of 1 ml hydrochloric acid per 10 ml solvent (1:10) is also used.

The acid is added in small portions with constant stirring. If the reaction mass becomes too thick, it is diluted with acetone. The mixture should be liquid enough to acidify the free base of 4-MMC uniformly. White gas (HCl) is actively released during this procedure. Respiratory and eye protection should be worn. To minimize the release of gas, it is recommended to cool the solution. During the acidification process, it is important to control the pH. At a pH of 5.5-6, acidification is stopped. The mixture is placed in a freezer for several hours. After that, the product is filtered and dried. The pH is controlled with pH indicator paper.

Working conditions:

- Air temperature 20-24 °C;

- Relative humidity <60%;

- Well ventilated room (with air inlet/exhaust hood);

- Access to water and electricity;

- Bromination;

- Methylamination;

- Separation/cleaning of free base;

- Acidification;

1000g of 4'-methylpropyrophenone (cas 5337-93-9) and 3000 ml of DCM are placed in a 10 l flask and shaken until a homogeneous solution is obtained.

A portion of bromine (Br2) 1000 g, 330 ml is poured into a dropping funnel.

It is important to know: Working with bromine requires special safety measures because the substance is highly corrosive and toxic. Any surface that comes into contact with bromine will be completely ruined. It is best to use a long graduated pipette or a graduated cylinder to measure the volume of this substance. Bromination should be carried out in the open air or in a well-ventilated room because bromine is very volatile. The procedure is not complicated but requires attention. All glassware used for bromine manipulations must be cooled and absolutely dry.

50 mL of hydrochloric acid (36% aqueous HCl) is added to the reaction mixture. This is the catalyst for the bromination reaction. Gentle stirring is activated and the addition of bromine is started.

The first portion of bromine, ~50 mL, is added. The solution turns brown and eventually discolors. This means that the bromination reaction has taken place. Wait for this moment, and do not pour in all the bromine at once to avoid a violent exothermic reaction with subsequent boiling of the solution.

Bromine is added from the dropping funnel to the solution dropwise, when the first portion of Br2 discolors, for a smooth reaction course. If the solution starts to boil, the addition of bromine should be stopped until the solution cools to 30-35 °C.

Important to know: Hydrogen bromide is released during bromination. It is a caustic (acidic) white gas. Respiratory and eye protection (full face mask) and a well ventilated fume hood are required.

It is necessary to make sure that the reaction is finished after all the bromine has been poured out: the reaction temperature stops rising, the solution stops discoloring. The reaction mixture is then stirred for 30-60 min.

The obtained solution is washed from the remaining bromine, which positively influences the quality of the final product. The reaction mixture is washed with an equal volume of 10% sodium thiosulfate (Na2S2O3) solution or 10% sodium bicarbonate (NaHCO3) solution. The solution is shaken well for 10 min, the layers are clearly separated. The lower organic layer is taken for further manipulations. The upper layer is discarded.

The reaction mixture is then washed with an equal volume of water to neutral pH. The washing procedure of the organic layer can be repeated several times, if necessary. The reaction yield of 2-Bromo-4'-methylpropyrophenone (cas 1451-82-7) is ~1400g, which is already dissolved in DCM.

Methylamination

A 40% aqueous solution of methylamine is added to the above reaction solution. This reaction is also exothermic, so the methylamine is added at a slow rate to prevent the solution from boiling. This influences the yield of the reaction. An excess of methylamine is taken up as some of it evaporates during the reaction. The average ratio is 2 ml per 1g of 2-Bromo-4'-methylpropyrophenone. 2800 ml of 40% aqueous methylamine solution is added to 1400 g of 2-Bromo-4'-methylpropyrophenone. The methylamine is added through a dropping funnel in a fine flow or divided into 2-3 portions and poured in equal parts with moderate stirring without splashing.

The reaction mixture is stirred for 2 hours at 40 °C.

Separation and purification of the free base

After processing the mixture from the previous part, the free base is washed and separated. The lower organic layer is separated from the upper aqueous layer. The organic layer is washed as described in step 7 (same procedures), the upper layer is discarded. The washing of the organic layer is repeated several times until the methylamine odor disappears.

The yield of the DCM solution of mephedrone free base (4-MMC) is ~3000 ml. If the organic layer is too small after methylamination, 1 to 2 L DCM is added. This will help to better extract the free base of 4-MMC. Then, separate the layers and discard the aqueous layer.

It is very important to separate the organic layer from the water. To be sure, you can put the DCM solution in the freezer, the remaining water will freeze and will be easy to separate. Also, you can dry your solution with anhydrous magnesium sulfate (MgSO4). If water remains, problems may arise with precipitation in the next step during acidification.

Acidification 14. The resulting free mephedrone base in DCM is treated with hydrochloric acid. The best method for salt production is HCl gasification. An aqueous solution of 35-38% hydrochloric acid HCl in acetone or isopropanol in the ratio of 1 ml hydrochloric acid per 10 ml solvent (1:10) is also used.

The acid is added in small portions with constant stirring. If the reaction mass becomes too thick, it is diluted with acetone. The mixture should be liquid enough to acidify the free base of 4-MMC uniformly. White gas (HCl) is actively released during this procedure. Respiratory and eye protection should be worn. To minimize the release of gas, it is recommended to cool the solution. During the acidification process, it is important to control the pH. At a pH of 5.5-6, acidification is stopped. The mixture is placed in a freezer for several hours. After that, the product is filtered and dried. The pH is controlled with pH indicator paper.