- Language

- 🇵🇱

- Joined

- Jun 17, 2024

- Messages

- 6

- Reaction score

- 15

- Points

- 3

- Deals

- 12

SYNTHESIS OF 4-FLUORO-P2NP FROM NITROETHANE AND 4-FLUOROBENZALDEHYDE

First of all I would like to thank G. Patton and WillD for their support and chemical and methodological knowledge which helped me to obtain very good synthesis results with great success!

Laboratory tools: 4-liter flat-bottomed flask, glass funnel, 8L pot, cheapest electric cooker, thermometer with 150*C scale, 2x 3000 ml beakers, 1 liter tall beaker, Allihn condenser + hoses and water pump + bowl (bucket) with cold water, 3-liter conical vacuum flask + 150 mm Buchner funnel + 150 mm quality filters + vacuum pump (water aspirator), PP drying trays (cuvettes), container for the obtained product (vacuum desiccator). Electric kettle.

Chemicals: Cyclohexylamine, 4-fluorobenzaldehyde, glacial acetic acid (GAA), nitroethane, distilled water, isopropanol

1. Cyclohexylamine - 200 ml is poured into a reaction flask (4L flat bottom flask) for

condensation.

2. Pour 1200 ml of 4-fluorobenzaldehyde into the reaction flask.

3. Pour 1200 ml of nitroethane into the reaction flask.

4. Glacial acetic acid (GAA) 400 ml is poured into the reaction flask. Remember that glacial acetic acid turns into a solid below 16*C. It is necessary to keep it in a liquid form.

5. A thick white mist may form during the reaction - stir the mixture holding the 4L beaker in both hands and vigorously making circular movements to mix everything - remember to have good ventilation.

6. Place the 8L pot on the electric stove and put a 1-2 cm high piece of wood in the pot (this is insulation from the hot bottom of the pot)

7. Place the 4L reaction flask in the pot, attach the neck of the reaction flask to the metal pin in the stand and place the Allihn reflux condenser on the reaction flask.

8. Turn on the water pump to start cooling in the Allihn reflux condenser.

9. Pour water into the electric kettle and boil the water until it starts to boil, then pour this water into the pot with the reaction flask to the height of the mixture poured into the reaction flask. (this process accelerates the stabilization of the expected temperature to 70-80*C.) We put the thermometer in a pot of hot water.

10. We turn on the electric stove to minimum heating and maintain the temperature of 70-80*C for 6 hours.

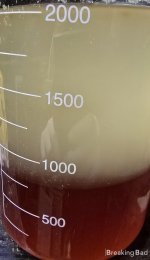

11. The color should change from light yellow to dark yellow

12. After a while, the reaction mixture is poured into a cooling container (2x 3L beaker). Crystallization time 24 hours. At a temperature of 0 - 4 *C.

13. 4-fluoro-P2NP is vacuum filtered on a Büchner funnel and a vacuum flask, after cooling and complete crystallization. It is best to use a circulating vacuum water pump water aspirator because it is resistant to corrosion (acetic acid is a strong corrosive agent)

14. The mother liquor (non-crystallized 4-fluoro-P2NP in a vacuum flask) is transferred to another vessel, and the crystallized 4-fluoro-P2NP on the Buchner funnel is washed with cold IPA.

15. 4-fluoro-P2NP is dried to a constant mass at room temperature for one day on a laboratory cuvette. Optionally, you can also use a desiccator and put 4-fluoro-P2NP in it, close the desiccator and connect the vacuum - thanks to this, the solvent from 4-fluoro-P2NP will initially evaporate strongly.

16. Then, distilled water is added to the non-crystallized 4-fluoro-P2NP in the beaker until additional 4-fluoro-P2NP crystals are obtained. If there are few crystals, it means that we have obtained a reaction with high efficiency. After adding water, 2 phases are formed: organic at the top and aqueous at the bottom. You can collect the top layer and freeze it or distill the solvent if necessary, but it is not necessary. Step 11 is optional (additional)

17. We obtain 1500 g of 4-fluoro-P2NP with a yield of 125%, taking into account 4-fluorobenzaldehyde

Additional conclusions. I think that extending the condensation reaction time from 6 to 8 hours will increase the reaction yield. During the reaction, you can stir the entire content vigorously every 2 hours (this would also increase the yield). I also think that reducing the amount of glacial acetic acid from 400 ml to 350 ml and cyclohexylamine from 200 ml to 180 ml will improve the final crystallization process of 4-fluoro-P2NP. We can also extend the crystallization time from 24 to 48 hours.

The advantages of this synthesis are the absence of a magnetic stirrer and the perfect final yield of 4-fluoro-P2NP.

First of all I would like to thank G. Patton and WillD for their support and chemical and methodological knowledge which helped me to obtain very good synthesis results with great success!

Laboratory tools: 4-liter flat-bottomed flask, glass funnel, 8L pot, cheapest electric cooker, thermometer with 150*C scale, 2x 3000 ml beakers, 1 liter tall beaker, Allihn condenser + hoses and water pump + bowl (bucket) with cold water, 3-liter conical vacuum flask + 150 mm Buchner funnel + 150 mm quality filters + vacuum pump (water aspirator), PP drying trays (cuvettes), container for the obtained product (vacuum desiccator). Electric kettle.

Chemicals: Cyclohexylamine, 4-fluorobenzaldehyde, glacial acetic acid (GAA), nitroethane, distilled water, isopropanol

1. Cyclohexylamine - 200 ml is poured into a reaction flask (4L flat bottom flask) for

condensation.

2. Pour 1200 ml of 4-fluorobenzaldehyde into the reaction flask.

3. Pour 1200 ml of nitroethane into the reaction flask.

4. Glacial acetic acid (GAA) 400 ml is poured into the reaction flask. Remember that glacial acetic acid turns into a solid below 16*C. It is necessary to keep it in a liquid form.

5. A thick white mist may form during the reaction - stir the mixture holding the 4L beaker in both hands and vigorously making circular movements to mix everything - remember to have good ventilation.

6. Place the 8L pot on the electric stove and put a 1-2 cm high piece of wood in the pot (this is insulation from the hot bottom of the pot)

7. Place the 4L reaction flask in the pot, attach the neck of the reaction flask to the metal pin in the stand and place the Allihn reflux condenser on the reaction flask.

8. Turn on the water pump to start cooling in the Allihn reflux condenser.

9. Pour water into the electric kettle and boil the water until it starts to boil, then pour this water into the pot with the reaction flask to the height of the mixture poured into the reaction flask. (this process accelerates the stabilization of the expected temperature to 70-80*C.) We put the thermometer in a pot of hot water.

10. We turn on the electric stove to minimum heating and maintain the temperature of 70-80*C for 6 hours.

11. The color should change from light yellow to dark yellow

12. After a while, the reaction mixture is poured into a cooling container (2x 3L beaker). Crystallization time 24 hours. At a temperature of 0 - 4 *C.

13. 4-fluoro-P2NP is vacuum filtered on a Büchner funnel and a vacuum flask, after cooling and complete crystallization. It is best to use a circulating vacuum water pump water aspirator because it is resistant to corrosion (acetic acid is a strong corrosive agent)

14. The mother liquor (non-crystallized 4-fluoro-P2NP in a vacuum flask) is transferred to another vessel, and the crystallized 4-fluoro-P2NP on the Buchner funnel is washed with cold IPA.

15. 4-fluoro-P2NP is dried to a constant mass at room temperature for one day on a laboratory cuvette. Optionally, you can also use a desiccator and put 4-fluoro-P2NP in it, close the desiccator and connect the vacuum - thanks to this, the solvent from 4-fluoro-P2NP will initially evaporate strongly.

16. Then, distilled water is added to the non-crystallized 4-fluoro-P2NP in the beaker until additional 4-fluoro-P2NP crystals are obtained. If there are few crystals, it means that we have obtained a reaction with high efficiency. After adding water, 2 phases are formed: organic at the top and aqueous at the bottom. You can collect the top layer and freeze it or distill the solvent if necessary, but it is not necessary. Step 11 is optional (additional)

17. We obtain 1500 g of 4-fluoro-P2NP with a yield of 125%, taking into account 4-fluorobenzaldehyde

Additional conclusions. I think that extending the condensation reaction time from 6 to 8 hours will increase the reaction yield. During the reaction, you can stir the entire content vigorously every 2 hours (this would also increase the yield). I also think that reducing the amount of glacial acetic acid from 400 ml to 350 ml and cyclohexylamine from 200 ml to 180 ml will improve the final crystallization process of 4-fluoro-P2NP. We can also extend the crystallization time from 24 to 48 hours.

The advantages of this synthesis are the absence of a magnetic stirrer and the perfect final yield of 4-fluoro-P2NP.

Attachments

Last edited: